Lowering Conveyor Noise with Roller Sleeves from Isolation Tech

Reduce noise, boost safety, and extend equipment life.

Noise is frequently underestimated in manufacturing environments, yet conveyor-generated sound—stemming from vibration, impact, and mechanical friction—poses measurable operational and health risks. Studies indicate that approximately one-third of industrial workers face an elevated risk of noise-induced hearing loss due to prolonged exposure to high-decibel systems.

Beyond auditory damage, sustained noise exposure correlates with increased fatigue, higher absenteeism rates, reduced situational awareness, and impaired verbal communication on the production floor. From a compliance perspective, inadequate noise monitoring and mitigation remain among OSHA’s most commonly cited violations, exposing facilities to regulatory penalties and unplanned costs.

Isolation Tech engineers low-noise conveyor solutions designed to reduce vibration, dampen acoustic output, and improve overall system efficiency—supporting safer operations, regulatory compliance, and long-term workforce sustainability.

Isolation Tech’s Low-Noise Electric Conveyor Solutions

Unchecked conveyor noise is more than a workplace nuisance. At best, it disrupts daily operations; at worst, it causes long-term harm to both employees and the bottom line. OSHA establishes permissible noise exposure limits at 90 dBA over an eight-hour shift, while NIOSH recommends a more protective threshold of 85 dBA, citing increased risk of hearing damage beyond this level. Many conveyor systems—particularly those operating with hard-contact rollers—regularly exceed these recommended and regulatory limits.

In high-noise environments, workers are more likely to miss critical auditory cues such as forklift warnings, emergency alarms, or verbal instructions. Routine conversations become strained, increasing the likelihood of errors and miscommunication. In some facilities, elevated accident rates have been directly linked to noise-related distractions and reduced situational awareness.

Workforce expectations further amplify the issue. Younger workers increasingly prioritize safe, comfortable, and ergonomically sound work environments, and persistent noise can undermine recruitment and retention efforts. When noise risks go unaddressed, organizations face a higher probability of hearing-related claims, rising turnover, and the loss of experienced personnel—costs that extend well beyond compliance.

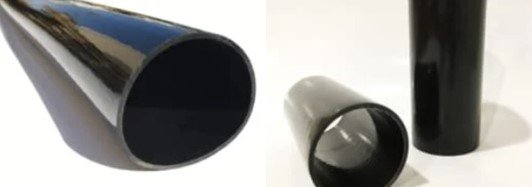

Isolation Tech stocks a range of roller cover sizes manufactured from natural rubber materials engineered to attenuate conveyor noise. In addition to reducing sound levels, these covers protect conveyed products from surface damage and increase friction between the product and roller, resulting in smoother, more consistent movement.

In many applications, replacing standard rollers with noise-attenuating roller covers can reduce overall conveyor noise by 20 to 40 decibels, depending on system configuration and operating conditions.

Roller Cover Options

Isolation Tech offers roller covers in both bulk and cut-to-length formats, with sizes designed to fit most roller conveyor systems. Manufactured from high-damped natural rubber, these covers help protect products from scratches while increasing grip for smoother, more consistent movement. In many applications, switching to Isolation Tech roller covers can reduce overall conveyor noise by 20 to 40 decibels. Many of our eCommerce roller cover products are available with same-day shipping for fast turnaround.

Ongoing Support

Isolation Tech supports conveyor system performance through expedited spare parts fulfillment and engineered maintenance programs targeting high-wear and fatigue-prone components. From the replacement of degraded roller covers to scheduled wear mitigation, Isolation Tech supplies application-specific components and technical expertise to minimize downtime, reduce noise generation, and maintain continuous, low-interruption system operation.

Beyond Noise—the ROI of a Safer, Smarter Workspace

Incremental improvements in workplace noise control deliver quantifiable operational and financial benefits:

Improved employee concentration and reduced missed auditory alerts

Lower risk of regulatory penalties and workers’ compensation claims associated with noise-induced hearing loss

Increased workforce attraction and retention in environments engineered for safety and comfort

Extended equipment service life with reduced unplanned maintenance and emergency repairs

Enhanced product protection during conveyance, minimizing rework, scrap, and damage-related claims

Low-noise conveyor systems contribute to a more sustainable operation by improving system reliability, workforce performance, and cost control. Organizations that invest in engineered noise reduction establish themselves as safety-focused, operationally mature employers.

Quiet, Reliable, Ready to Ship

Isolation Tech’s conveyor roller cover solutions are available online through our eCommerce platform, with many configurations shipping quickly. Customers can request a quote online. They can also order spare parts or connect with technical support through the site. That makes it easier to start building a quieter workspace.

Contact us to find out how we can provide the foundation for a quieter, safer, and more productive workplace.